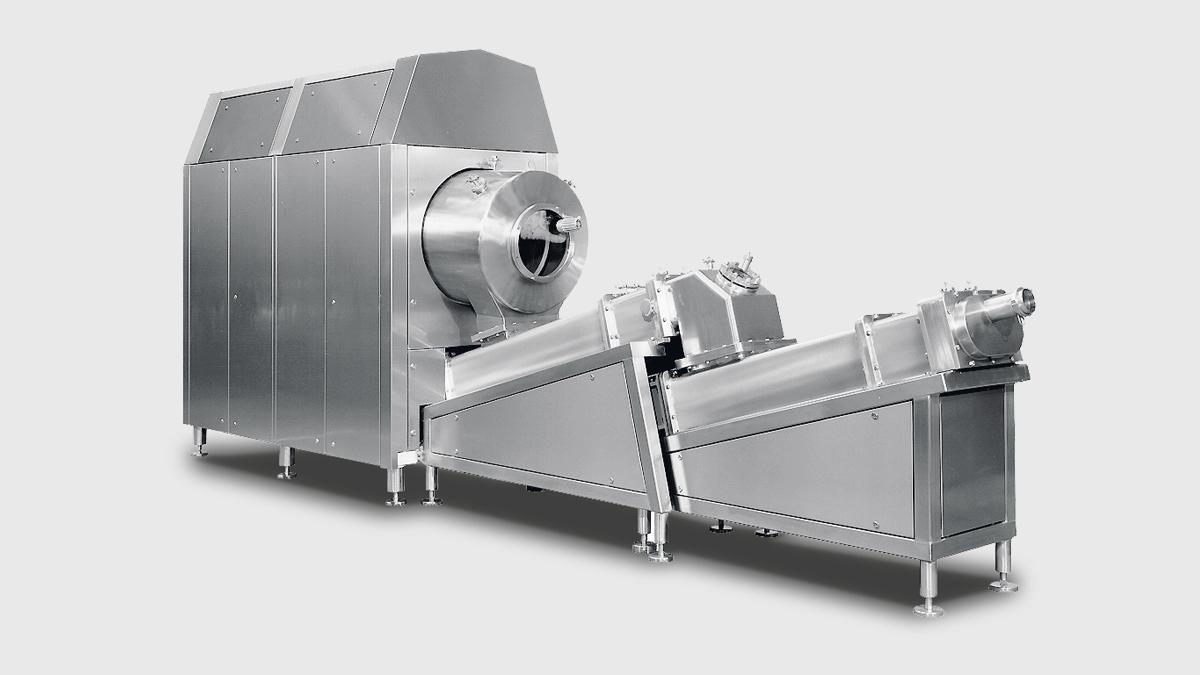

There are a few types of butter processing equipment available in the market. The most common ones are the batch type and the continuous type butter processors.

The batch type butter processors are mostly used in small-scale butter production. They are able to process a small quantity of butter at a time and are not suitable for large-scale production. The continuous type butter processors are mostly used in large-scale butter production. They can process a large quantity of butter at a time and are more efficient.

The benefits of using butter processing equipment are that it can help to improve the quality of the butter, and it can also help to improve the efficiency of the butter production process.

When choosing the right type of butter processing equipment for your business, you should consider the size of your business, the type of butter you want to produce, and the budget you have.

If you are looking for a butter processing equipment for your business, you can contact a professional company that specializes in butter processing.

When you contact a professional company that specializes in butter processing, they will be able to help you choose the right type of equipment for your business.

Butter is a dairy product made from the fat and protein content of milk. It is a solid at room temperature and is used as a spread, as an ingredient in baking, or as a cooking oil.

The process of making butter begins by separating the cream from milk. This can be done using a centrifuge or by letting milk sit until the cream rises to the top. Once the cream is separated, it is churned until it forms a solid. The churning process breaks down the fat cells in the cream and causes them to form a network that traps air and water. This results in a solid product with a high fat content.

The butter is then washed to remove any residual milk solids. This helps to improve the flavor and shelf life of the butter. After washing, the butter is typically salt-cured to improve flavor and act as a preservative.

The final step in the butter-making process is packaging. Butter is typically sold in sticks, blocks, or tubs. It can also be sold in bulk form.

The benefits of butter processing include:

-Dairy products are a good source of nutrition.

-Butter is a versatile ingredient that can be used in many different recipes.

-The machines used to make butter are typically very efficient, so the process is relatively quick and easy.

-Butter has a long shelf life and can be stored for a long time without going bad.

-Butter is a relatively inexpensive food product.