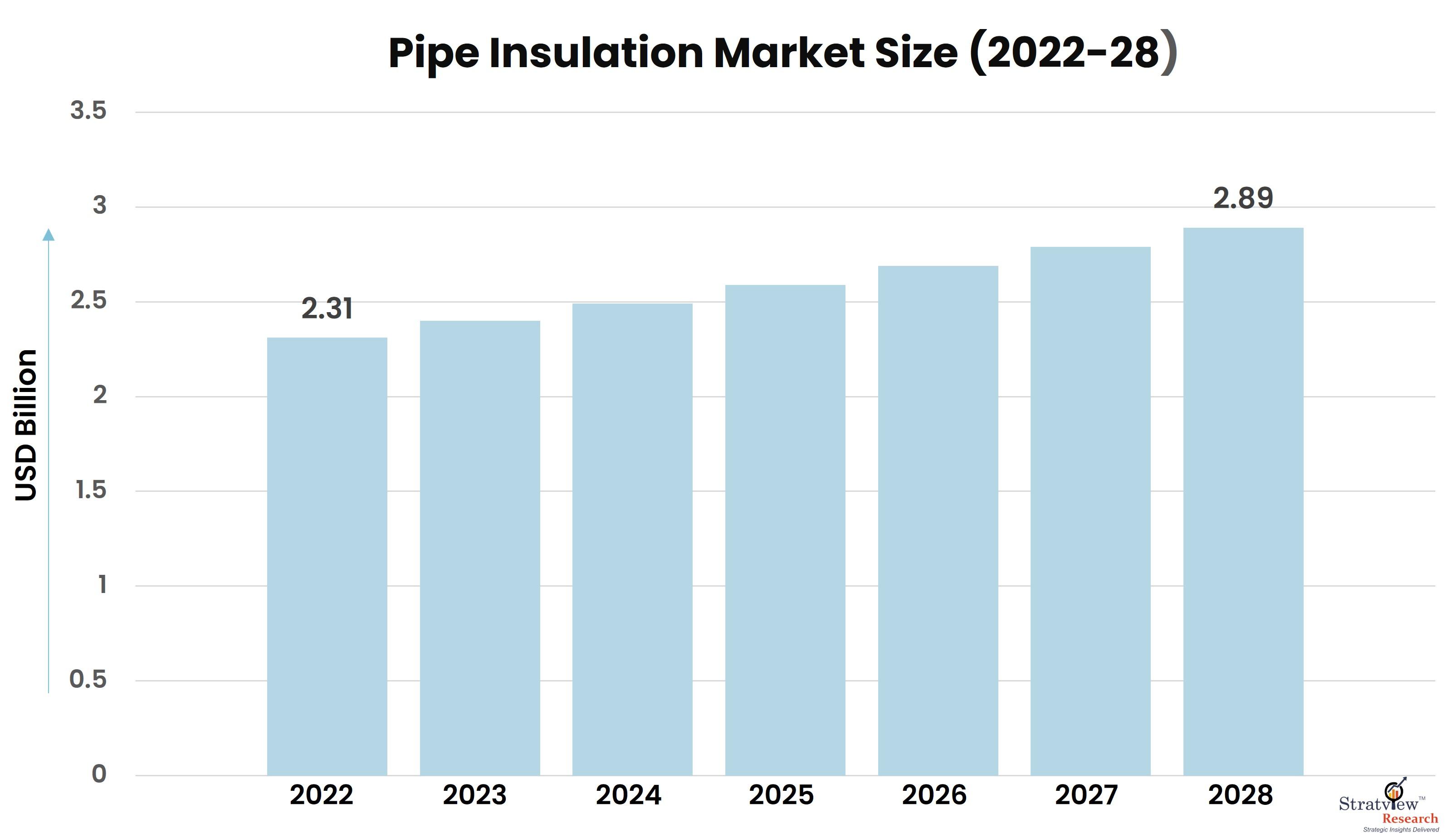

According to Stratview Research, the pipe insulation market was estimated at USD 2.31 billion in 2022 and is likely to grow at a significant CAGR of 3.78% during 2023-2028 to reach USD 2.89 billion in 2028.

In the intricate network of pipes that weave through buildings, industrial facilities, and infrastructure, the unsung hero is insulation. As an indispensable component, insulation plays a crucial role in maintaining temperature, conserving energy, and ensuring the efficiency of various processes. This article delves into the ins and outs of insulation, providing a comprehensive exploration of the pipe insulation industry, its applications, materials, and the pivotal role it plays in diverse sectors.

Foundations of Pipe Insulation: At its core, pipe insulation is about creating a thermal barrier to prevent heat loss or gain in pipes. It involves wrapping pipes with materials designed to reduce heat transfer, maintaining the desired temperature of the fluid flowing within, and contributing to energy conservation.

Diverse Applications Across Industries: The pipe insulation industry spans a broad spectrum of applications, catering to the unique needs of different sectors. From the energy industry, where insulated pipes are crucial for transporting oil and gas, to residential plumbing systems that benefit from reduced heat loss, the versatility of pipe insulation is evident.

Materials That Matter: The materials used in pipe insulation are diverse and tailored to specific requirements. Traditional materials like fiberglass and mineral wool continue to be popular, while advancements have introduced aerogels, foams, and elastomeric materials that offer enhanced thermal resistance and durability.

Energy Efficiency at the Forefront: Energy efficiency is a primary driver in the pipe insulation industry. Properly insulated pipes contribute to significant energy savings by reducing heat loss during the transportation of hot fluids and minimizing the energy needed to maintain desired temperatures.

Cost-Effective Solutions: The ins and outs of the pipe insulation industry highlight its cost-effectiveness. While there is an initial investment in insulation materials and installation, the long-term savings in reduced energy consumption often far outweigh the upfront costs, making it a financially prudent choice.

Preventing Condensation and Corrosion: Beyond temperature regulation, insulation serves as a barrier against condensation and corrosion. Insulated pipes prevent moisture from forming on the pipe's surface, reducing the risk of corrosion and ensuring the longevity of the infrastructure.

Environmental Sustainability: Environmental considerations are increasingly shaping the pipe insulation industry. Manufacturers are developing insulation materials with recycled content, and there is a growing emphasis on creating sustainable solutions that minimize environmental impact throughout the lifecycle of the insulation.

Ease of Installation: The ins and outs of pipe insulation include considerations of installation. Modern insulation systems often feature prefabricated components, facilitating ease of installation and ensuring uniformity, which is crucial for achieving optimal thermal performance.

Fire Safety Measures: Fire safety is a paramount concern in the pipe insulation industry. Insulation materials with fire-resistant properties are gaining prominence, providing an additional layer of protection in settings where fire safety is a critical consideration.

Regulatory Compliance and Standards: The pipe insulation industry operates within a framework of regulatory standards and compliance. Manufacturers adhere to specifications that ensure the insulation meets safety, performance, and environmental standards, contributing to responsible and reliable insulation practices.

Conclusion:

The ins and outs of insulation in the pipe insulation industry unveil a dynamic landscape where efficiency, versatility, and sustainability intersect. Whether in industrial complexes, commercial buildings, or residential spaces, the role of insulation is foundational to the functionality and longevity of piping systems. As the industry continues to evolve, embracing new materials, technologies, and sustainable practices, the ins and outs of insulation remain integral to creating a well-insulated world that balances energy efficiency, environmental responsibility, and cost-effectiveness.