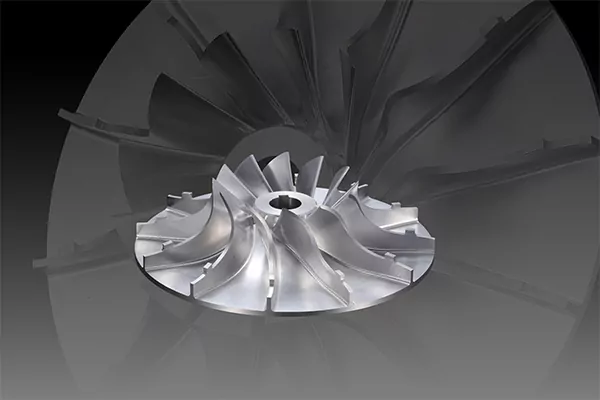

Now that you're wondering, let's look at this cnc manufacturing.

In the realm of CNC manufacturing, the application of lean principles is crucial for achieving optimal output and reducing waste. By implementing lean manufacturing techniques, CNC operations can streamline processes, minimize downtime, and enhance overall efficiency. Let's delve into the various strategies and methodologies that can be employed to maximize productivity and minimize waste in CNC operations.

The Importance of Lean Principles in CNC Operations

Employing lean principles in CNC operations is essential for eliminating non-value-added activities and optimizing the use of resources. By focusing on continuous improvement and waste reduction, manufacturers can enhance their competitiveness and meet the ever-increasing demands of the market. Lean manufacturing fosters a culture of efficiency and innovation, driving CNC operations towards greater productivity and profitability.

Strategies for Waste Reduction in CNC Operations

One of the key strategies for waste reduction in CNC operations is the implementation of just-in-time production. By producing only what is needed, when it is needed, manufacturers can minimize inventory holding costs and reduce the risk of overproduction. Additionally, the adoption of single-piece flow manufacturing can further eliminate waste by ensuring a continuous and smooth production process, thereby reducing lead times and enhancing overall efficiency.

Optimizing Output through Continuous Improvement

Continuous improvement is at the core of lean principles in CNC operations. By embracing methodologies such as kaizen and total productive maintenance, manufacturers can systematically enhance their processes and equipment to achieve higher levels of productivity. Through the proactive involvement of employees and the implementation of standardized work procedures, CNC operations can continuously evolve and adapt to meet the dynamic demands of the market.

Utilizing Data-Driven Decision Making for Enhanced Efficiency

Another critical aspect of lean principles in CNC operations is the utilization of data-driven decision making. By leveraging key performance indicators and value stream mapping, manufacturers can gain valuable insights into their processes and identify opportunities for improvement. This data-driven approach enables informed decision making, leading to the implementation of targeted solutions that drive efficiency and waste reduction in CNC operations.

In conclusion, the application of lean principles is paramount for achieving optimal output and waste reduction in CNC operations. By embracing strategies for waste reduction, optimizing output through continuous improvement, and utilizing data-driven decision making, manufacturers can enhance their competitiveness and drive sustainable growth. The journey towards lean manufacturing in CNC operations is a continuous process of improvement and innovation, ultimately leading to enhanced productivity and profitability.