The Difference Between Mechanical Desktop Industrial Endoscope

Desktop Industrial Endoscope is a commonly used non-destructive testing instrument. It completes imaging, photography, shooting and operation functions through imaging algorithms. It is portable, integrated, simple and easy to operate, which greatly reduces the user's work intensity and improves detection efficiency. With direct visualization and photo and video storage functions, it is widely used in energy and power, petrochemical, special inspection industry, machinery casting, aerospace, food and medicine machinery and other industries.To get more news about video borescope, you can visit seesemborescopes.com official website.

It is often used to detect parts that cannot be directly seen by the human eye, such as pipes, engines, fuel tanks, castings, etc. Check its inner and outer surfaces for cracks, corrosion, rust, welding defects, and check its interior for blockages and foreign objects. Industrial endoscopes can be divided into mechanical control and electrical control according to the probe-oriented control method. The SM40 series and SM50 series on the production line are the excellent representatives of these two industrial endoscopes. SM40 series high-definition industrial endoscope adopts independent and innovative embedded imaging system and mechanical guidance control. Similar to the electrical products in the embedded imaging system, the probe control system uses manual mechanical operation to directly pull the wire rope inside the pipeline to control the steering of the probe, so it is simpler to use than the electric operation, and the reset also requires manual operation.

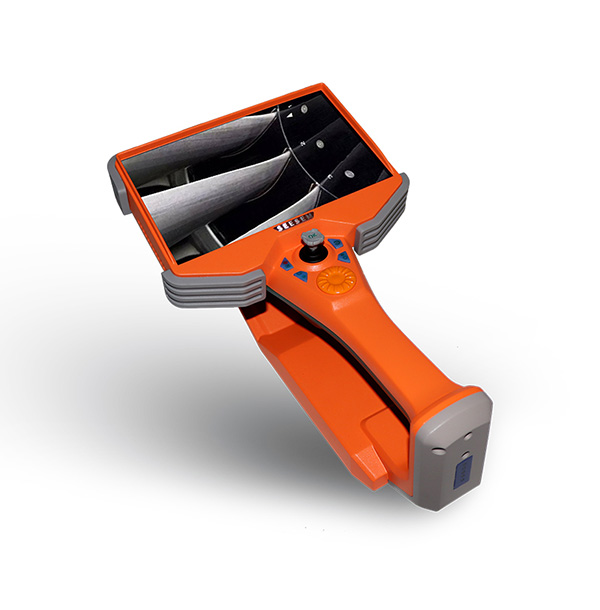

This series is lighter because there is no core component of electronic control - the steering gear system, which makes it easier to replace pipes of various specifications. Therefore, the SM40 series products can be selected when various pipe diameters are required to be tested, and can be used for various purposes, which are more economical and achieve maximum cost savings. The electric million ultra-high-definition industrial endoscope SM50 series adopts the independent and innovative embedded imaging system and electric probe control system, and completes imaging, photography, video recording and operation functions through imaging algorithms. As one of the main components of the probe control system, the steering gear with control response can pull the steel wire in the pipeline in multiple directions to complete the 360 steering control of the probe. The electronic control system can automatically reset, adjust the steering speed of the probe, and adjust it gradually.

It can investigate in all directions without dead angle, and the operation is more sensitive. Through the research on the zero-delay, no-idle travel variable-speed transmission mechanism, the entire transmission mechanism is driven by rack and pinion. This design ensures constant instantaneous transmission ratio, high stability, accurate and reliable transmission motion, wide transmission power and speed range, high transmission ratio and transmission efficiency, compact structure, reliable operation and long service life. In general, the electric industrial endoscope operating system has high definition, accurate steering, convenient operation, simple and easy operation, strong portability and strong integration, which greatly reduces the user's work intensity and improves the detection efficiency.